An animal feed production line is a highly specialized setup designed to manufacture various types of animal feeds in a streamlined, automated process. The main purpose of these production lines is to transform raw agricultural materials like corn, barley, soybeans, and other additives into formulated, pelleted, or powdered feed suitable for a wide range of animal types.

Uses and Significance of Animal Feed Production Lines

The primary use of an animal feed production line is to produce balanced and nutritious feed capable of ensuring optimal growth, health, and output of livestock. These lines are critical for the consistent production of feed in large volumes, which helps in maintaining the supply chain for poultry, dairy, and meat industries globally.

Market and Profit Analysis

The global animal feed market size was valued at over USD 400 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of around 3.7% from 2022 to 2027.

This growth is propelled by increasing livestock production and the rising demand for high-quality meat products. Profit margins in animal feed production are significantly enhanced by reducing production downtime, optimizing feed formulations, and adopting advanced manufacturing technologies.

Technical Specifications and Process Flow

The technical process of an animal feed production line typically involves several key stages:

- Raw Material Intake and Preparation: Ingredients are received, inspected, and stored. They are then conveyed to the grinding unit to produce a fine powder.

- Mixing: A batch mixer combines the powdered ingredients uniformly to ensure even distribution of nutrients.

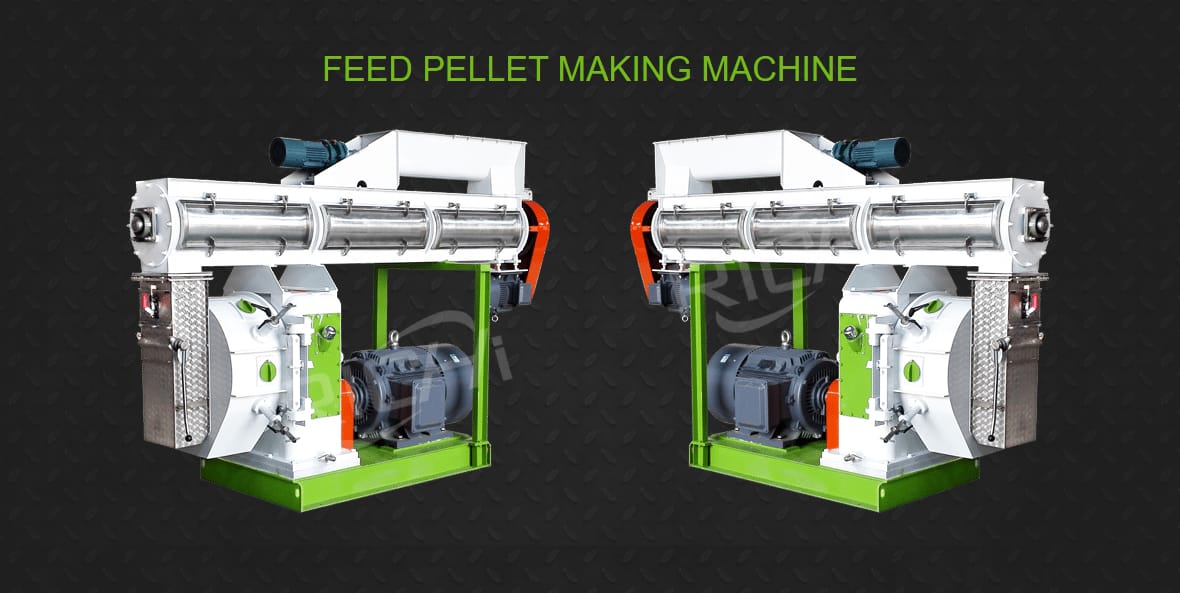

- Pelletizing (using Ring Die Technology): The mixed feed is then conditioned at high temperature and moisture before being fed into a ring die pellet mill where it is compressed into pellets.

- Cooling and Screening: The hot pellets are cooled to room temperature to harden and stabilize them. They are then screened to separate fines and broken pellets.

- Packaging: The final pellets are weighed and packed for storage or shipment.

Classification and Applications in the Industry

Feed production lines are categorized based on their capacity (typically ranging from 1 to 60 tons per hour) and the type of animals they cater to (e.g., poultry, swine, cattle). Each line is designed to meet specific regulatory standards pertaining to animal nutrition and safety.

Project Case Studies and RICHI Machinery Solutions

- Design Problem: A 40-ton production line had inefficiencies in material flow. Solution: RICHI Machinery redesigned the layout to optimize the gravity feed, reducing reliance on conveyors and energy consumption.

- Site Issue: A compact site with limited expansion capacity. Solution: RICHI implemented a vertical design strategy, allowing the plant to expand upwards rather than outwards, saving space and reducing footprint.

- Equipment Challenge: High wear and tear in the pelletizing unit. Solution: RICHI upgraded the ring die materials to a more durable alloy and introduced a variable speed drive to control the pellet mill more effectively.

- Installation and Commissioning: Misalignments during setup led to operational delays. Solution: RICHI provided specialized on-site training and used precision laser alignment tools during installation to ensure seamless setup.

- After-sales Issue: Customers needed ongoing support for process optimization. Solution: RICHI established a 24/7 customer service center and scheduled regular maintenance visits.

Choosing RICHI Machinery and Its Turnkey Capabilities

Selecting a supplier for an animal feed production line involves evaluating their capability to deliver customized, comprehensive, and turnkey solutions.

RICHI Machinery excels in providing these services, ensuring that every aspect from design to installation and after-sales support is covered. They offer adaptable configurations tailored to specific operational needs, maximizing both efficiency and productivity.

Benefits of Opting for RICHI Machinery

Choosing RICHI Machinery offers several advantages:

- Customization: Ability to tailor production lines to the specific needs of the client, including layout and machinery specifications.

- Turnkey Solutions: Comprehensive project management from concept to completion with minimal disruption.

- Advanced Technology: Use of cutting-edge technology in machinery and process control to maximize yield and quality.

Conclusion: Why Choose an Animal Feed Production Line?

Investing in a modern animal feed production line is essential for businesses aiming to capitalize on the growing demand for animal products. A well-designed line enhances productivity, ensures feed quality, and reduces waste, thereby maximizing profitability.

FAQs About Animal Feed Production Lines

What is the advantage of using a ring die over a flat die in feed pelleting?

Ring dies provide more uniform heat and pressure distribution, producing higher quality pellets, especially for large-scale production.

How does RICHI Machinery customize a feed production line for a new client?

RICHI assesses the client’s needs based on feed type, production capacity, and space constraints to design a customized solution.

What post-installation support does RICHI offer?

RICHI provides comprehensive after-sales service, including spare parts, technical support, and regular maintenance.

This detailed, data-backed, and analytically written article aims to inform and guide stakeholders in the animal feed production industry, emphasizing the technical and economic benefits of advanced production lines and the advantages of partnering with RICHI Machinery.