Global Wood Pellet Machine Manufacturing Industry Market Analysis Report 2025

The global wood pellet machine manufacturing industry is experiencing unprecedented growth driven by the expanding…

The global wood pellet machine manufacturing industry is experiencing unprecedented growth driven by the expanding wood pellet market and increasing demand for renewable energy solutions. As the backbone of the biomass pellet production ecosystem, wood pellet machine manufacturers are positioned to capitalize on the burgeoning demand for efficient, high-capacity pelletizing equipment. This comprehensive analysis examines…

Introduction Chicken manure, rich in nitrogen, phosphorus, potassium, and organic matter, is one of the most valuable organic resources in agriculture. However, due to its high moisture, pathogens, and unpleasant odor, it cannot be applied directly to the soil. A scientifically designed chicken manure pellet organic fertilizer production line transforms raw poultry waste into safe,…

1. Introduction In the organic fertilizer production industry, improving the production capacity of organic fertilizer pelletizers is of great significance for meeting the growing market demand, reducing production costs, and enhancing the competitiveness of enterprises. Organic fertilizer pelletizers are complex mechanical devices, and their production capacity is affected by a variety of factors. Among them,…

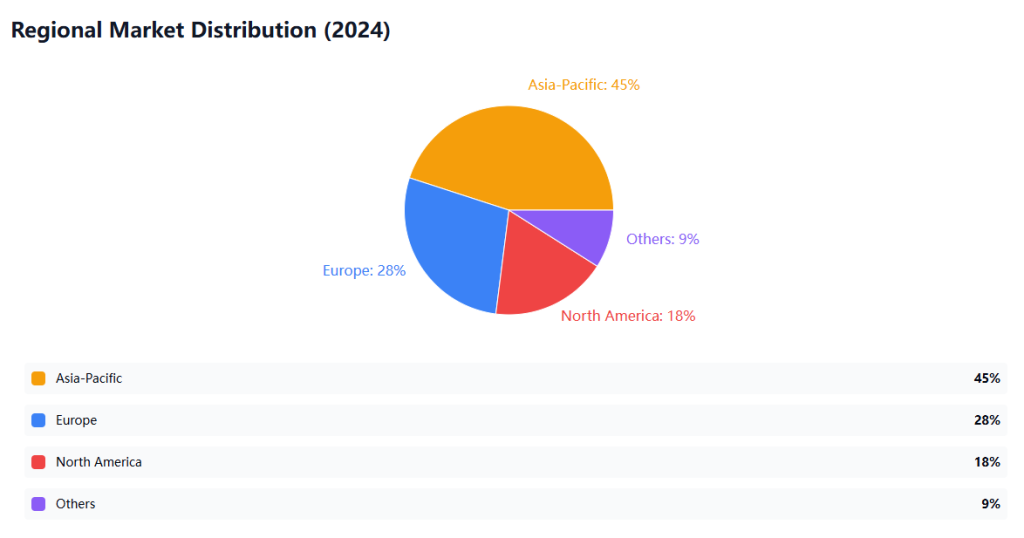

The global pellet mill industry is booming, driven by the urgent demand for sustainable energy solutions, efficient livestock feed production, and advancements in biomass processing technology. According to Grand View Research, the market size reached $2.3 billion in 2024, with a projected CAGR of 5.1% through 2030. Key growth factors include stricter carbon emission regulations, the rise of…

Introduction to Fish Feed Making Machine In the expanding realm of aquaculture, the fish feed making machine has emerged as a pivotal tool. Primarily designed to produce customized fish feed, these machines cater to the specific dietary requirements of various fish species. This apparatus functions by combining raw materials such as fish meal, soybean, and…

The production of high-quality pig feed is essential for farmers aiming to optimize growth rates, improve health, and enhance overall productivity in their livestock. To achieve this, specialized animal feed processing machines are required to efficiently process various ingredients into nutritious and palatable feed. This article discusses the key machines suitable for producing pig feed,…

The production of grass pellets is a vital process in the biomass energy sector and animal feed industry, providing a renewable and efficient source of energy and nutrition. The efficiency of a grass pellet machine plays a significant role in determining the quality of the final product. This article explores the relationship between production efficiency…

The production of hay pellets has gained popularity due to their applications in biomass energy and animal feed. Setting up a hay pellet machine involves various costs, which can vary significantly depending on the region. Understanding these cost differences is crucial for potential investors and operators in the feed production industry. This article explores the…

The production of bagasse pellets has gained traction as a sustainable solution for biomass energy and animal feed. Bagasse, the fibrous residue left after sugarcane processing, is an abundant and renewable resource. However, to ensure profitability and sustainability, it is essential to optimize the production process of bagasse pellet machines. This article discusses various strategies…

The cotton stalk pellet machine is an essential piece of equipment for converting agricultural waste, specifically cotton stalks, into high-density fuel pellets. This process not only helps in waste management but also contributes to renewable energy production. However, the total cost of a cotton stalk pellet machine can vary significantly based on several factors. Understanding…