The shrimp aquaculture industry has experienced significant growth in recent years, leading to an increased demand for high-quality shrimp feed. Shrimp feed pellet machines play a crucial role in modern shrimp feed factories, enabling efficient production of nutritious and easily digestible feed for various shrimp species.

This article explores the application of shrimp feed pellet machines in shrimp feed factories, highlighting their importance, benefits, and impact on the industry.Importance of Shrimp Feed Pellet MachinesShrimp feed pellet machines are essential equipment in shrimp feed factories for several reasons:

- Efficient Production: These machines can produce large quantities of shrimp feed pellets quickly and consistently, meeting the demands of commercial shrimp farming operations.

- Nutritional Control: By precisely mixing and processing ingredients, these machines help maintain the nutritional balance required for optimal shrimp growth and health.

- Feed Consistency: Pellet making machines ensure uniform size, shape, and density of feed pellets, which is crucial for proper feeding and digestion in shrimp.

- Customization: Modern machines allow for the production of various pellet sizes to suit different shrimp species and life stages.

- Cost-Effectiveness: In-house production of shrimp feed using these machines can significantly reduce feed costs for aquaculture operations.

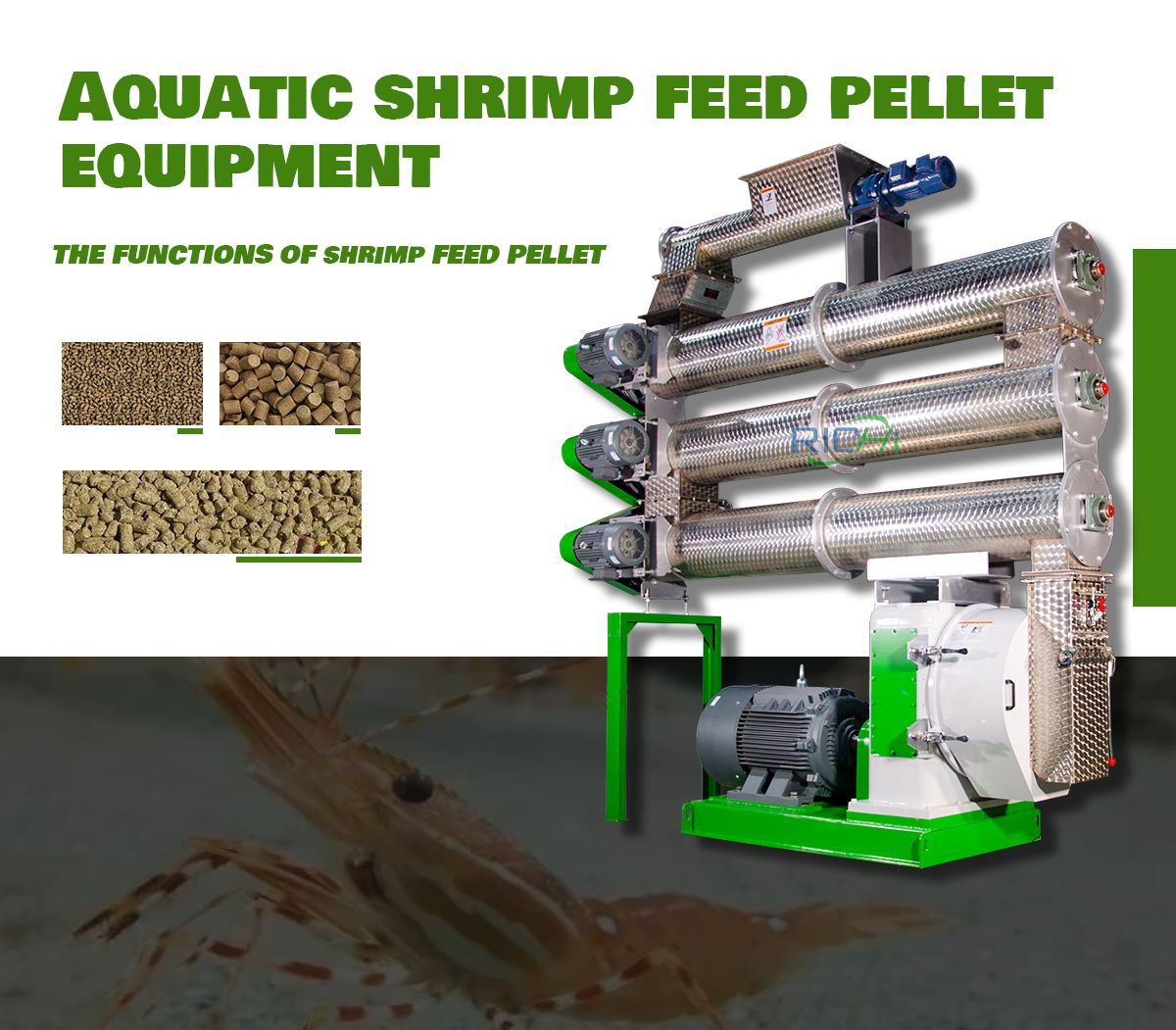

Types of Shrimp Feed Pellet MachinesShrimp feed factories typically use two main types of feed pellet machines:

- Ring Die Pellet Mills:

- Primarily produce sinking pellets

- Suitable for high-volume production of dense pellets

- Generally more energy-efficient

- Extruders:

- Capable of producing slow-sinking and sinking pellets

- Use high temperature and pressure for better starch gelatinization and protein denaturation

- Ideal for producing high-quality, easily digestible feed

Application Process in Shrimp Feed FactoriesThe application of shrimp feed pellet machines in feed factories typically involves the following steps:

- Raw Material Preparation:

- Ingredients are ground to the appropriate particle size

- Dry ingredients are mixed according to the feed formulation

- Conditioning:

- The mixture is preconditioned with steam to adjust moisture and temperature

- This step is crucial for achieving proper pellet formation and water stability

- Pelleting or Extrusion:

- In pellet mills, the mixture is compressed through a die to form pellets

- Extruders cook and form the mixture into pellets under high temperature and pressure

- Cutting:

- Pelleted or extruded feed is cut to the desired length

- Drying:

- Pellets are dried to reduce moisture content and improve stability

- Cooling:

- Dried pellets are cooled to ambient temperature

- Coating (optional):

- Oils, vitamins, or other additives may be applied to the cooled pellets

- Packaging:

- The finished feed is packaged for storage or distribution

Benefits of Using Shrimp Feed Pellet Machines

The application of these machines in shrimp feed mill factories offers numerous benefits:

- Improved Feed Quality:

- Better control over ingredient mixing and processing leads to higher quality feed

- Enhanced digestibility due to starch gelatinization and protein denaturation in extruded feeds

- Increased Productivity:

- High-capacity machines can produce large volumes of feed to meet growing demand

- Automated processes reduce labor requirements and increase efficiency

- Flexibility in Production:

- Ability to produce different sizes of pellets for various shrimp life stages

- Easy adjustment of formulations to meet specific nutritional requirements

- Better Feed Management:

- Uniform pellet size and density allow for more accurate feeding and reduced waste

- Improved water stability of pellets reduces nutrient leaching and water pollution

- Cost Reduction:

- In-house production reduces reliance on expensive commercial feeds

- Bulk ingredient purchasing and efficient processing lower overall feed costs

- Quality Control:

- Direct control over the production process ensures consistent feed quality

- Ability to quickly adjust formulations in response to shrimp performance or market conditions

- Environmental Benefits:

- Improved feed conversion ratios reduce waste and environmental impact

- Better water stability of pellets reduces water pollution in shrimp ponds

Challenges and ConsiderationsWhile shrimp feed pellet machines offer numerous advantages, feed factories must also consider some challenges:

- Initial Investment:

- High-quality machines require significant upfront investment

- Technical Expertise:

- Proper operation and maintenance of these machines require skilled personnel

- Energy Consumption:

- Some machines, particularly extruders, can be energy-intensive

- Formulation Complexity:

- Creating optimal feed formulations for different shrimp species and life stages can be challenging

- Raw Material Quality:

- Consistent quality of raw materials is crucial for producing high-quality feed

Technological AdvancementsRecent advancements in shrimp feed pellet machine technology have further enhanced their capabilities:

- Improved Moisture Control:

- RICHI shrimp feed pellet machines can handle high moisture feed mash up to 17%, ensuring better pellet quality and water stability.

- Energy Efficiency:

- New generation systems offer energy-saving features, such as reusing cooler exhaust air in the dryer.

- Enhanced Conditioning:

- Advanced conditioning systems, including multi-layer conditioners, improve feed quality and pellet durability.

- Precision Control:

- Modern machines offer precise control over processing parameters, allowing for consistent production of high-quality feed.

Future TrendsThe application of shrimp feed pellet machines in feed factories is likely to see several advancements:

- Increased Automation:

- Integration of AI and IoT technologies for more efficient and precise production

- Sustainability Focus:

- Development of machines capable of processing alternative protein sources and sustainable ingredients

- Energy Efficiency:

- Continued innovations in machine design to reduce energy consumption and improve sustainability

- Precision Nutrition:

- Advanced systems for real-time adjustment of feed formulations based on shrimp performance data

ConclusionShrimp feed pellet machines have become indispensable in modern shrimp feed factories. Their application has revolutionized the production of shrimp feed, enabling the aquaculture industry to meet the growing demand for high-quality, nutritious feed efficiently and cost-effectively. As technology continues to advance, these machines will play an even more crucial role in supporting sustainable shrimp farming practices and meeting the nutritional needs of farmed shrimp species.The successful application of shrimp feed pellet machines in feed factories requires a combination of quality equipment, expert knowledge in feed formulation, and efficient production processes. As the shrimp farming industry continues to grow and evolve, the role of these machines in producing specialized, high-performance feeds will become increasingly important, driving innovation in both machine design and feed technology.