In the ever-evolving landscape of manufacturing and processing industries, twin screw extruders have emerged as versatile and indispensable pieces of equipment. These powerful machines are designed to efficiently process a wide range of materials, from plastics and rubbers to food products and pharmaceuticals. As Australia’s industrial sector continues to grow and diversify, the demand for high-quality twin screw extruders has surged, prompting a thriving market for these specialized machines.

Twin screw extruders are characterized by their unique design, featuring two parallel screws that rotate in the same or opposite directions, depending on the application. This configuration allows for precise control over material flow, temperature, and pressure, enabling the production of consistent and high-quality products. With their ability to handle a variety of materials and their adaptability to different processing requirements, twin screw extruders have become invaluable assets across various industries in Australia.

The Plastics and Polymer Industry

One of the primary industries driving the demand for twin screw extruders in Australia is the plastics and polymer sector. These machines play a crucial role in the compounding, melting, and extrusion of various plastic materials, including thermoplastics, elastomers, and composites. Twin screw extruders are widely used in the production of plastic pipes, profiles, sheets, and films, as well as in the manufacturing of plastic components for industries such as automotive, construction, and packaging.Australian manufacturers and processors in the plastics industry rely on twin screw extruders for their ability to handle a wide range of materials, including recycled plastics, and their capability to incorporate additives, fillers, and reinforcements into the polymer matrix. This versatility allows for the creation of customized plastic products with specific properties, such as enhanced strength, durability, or thermal resistance.

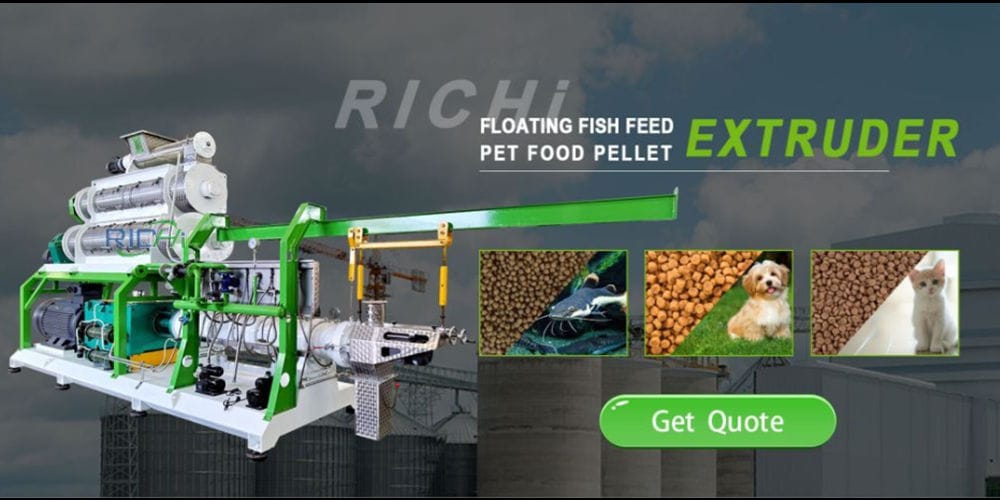

Related post:https://www.richipelletmachine.com/floating-fish-feed-extruder-machine/

The Food and Pharmaceutical Industries

Beyond the plastics industry, twin screw extruders have also found widespread applications in the food and pharmaceutical sectors in Australia. In the food industry, these machines are used for the extrusion of various food products, including snacks, cereals, pet foods, and meat analogues. The precise temperature and pressure control offered by twin screw extruders ensures consistent product quality, texture, and flavor, while also enabling the incorporation of functional ingredients and additives.In the pharmaceutical industry, twin screw extruders play a vital role in the production of drug delivery systems, such as sustained-release tablets and transdermal patches. The extrusion process allows for the precise mixing and dispersion of active pharmaceutical ingredients (APIs) with excipients, ensuring uniform drug distribution and controlled release profiles.

The Rubber and Elastomer Industry

Australia’s rubber and elastomer industry also relies heavily on twin screw extruders for the compounding and processing of various rubber materials. These machines are used in the production of rubber components for industries such as automotive, construction, and industrial applications. Twin screw extruders enable the efficient mixing and dispersion of fillers, reinforcements, and additives into the rubber matrix, resulting in products with enhanced mechanical properties, durability, and performance characteristics.

Key Factors to Consider When Purchasing Twin Screw Extruders

When exploring twin screw extruder for sale Australia, it’s essential to consider several key factors to ensure the machine meets your specific processing requirements and delivers optimal performance:

- Screw Configuration: Twin screw extruders can have co-rotating or counter-rotating screw configurations, each suited for different applications and materials. Evaluating your processing needs and material characteristics is crucial to selecting the appropriate screw configuration.

- Throughput Capacity: Determine the desired throughput capacity based on your production volume requirements. Twin screw extruders are available in various sizes and configurations to accommodate different output capacities.

- Material Compatibility: Ensure that the twin screw extruder is compatible with the materials you plan to process, considering factors such as temperature requirements, shear sensitivity, and potential corrosion or abrasion issues.

- Automation and Control Systems: Modern twin screw extruders often incorporate advanced automation and control systems for precise monitoring and adjustment of process parameters. Evaluate the level of automation and user-friendliness to optimize efficiency and product quality.

- Energy Efficiency: As energy costs continue to rise, consider the energy efficiency of the twin screw extruder, including features such as energy recovery systems and optimized screw designs for reduced power consumption.

- Maintenance and Support: Reliable after-sales support, availability of spare parts, and comprehensive maintenance services are crucial for ensuring the longevity and optimal performance of your twin screw extruder.

- Regulatory Compliance: Depending on your industry, ensure that the twin screw extruder complies with relevant Australian and international regulations, standards, and certifications related to safety, emissions, and product quality.

By carefully evaluating these factors and working with reputable suppliers and manufacturers, Australian businesses can acquire twin screw extruders that meet their specific processing needs, enhance productivity, and contribute to the growth and competitiveness of their respective industries. As Australia’s manufacturing and processing sectors continue to evolve, the demand for advanced and efficient equipment like twin screw extruders is expected to rise.

By staying abreast of the latest technological developments and industry trends, Australian companies can leverage the capabilities of these versatile machines to drive innovation, improve product quality, and maintain a competitive edge in both domestic and global markets.