The global wood pellet machine manufacturing industry is experiencing unprecedented growth driven by the expanding wood pellet market and increasing demand for renewable energy solutions. As the backbone of the biomass pellet production ecosystem, wood pellet machine manufacturers are positioned to capitalize on the burgeoning demand for efficient, high-capacity pelletizing equipment.

This comprehensive analysis examines the wood pellet machine manufacturing landscape, focusing on equipment suppliers, technology providers, and complete production line manufacturers. The industry serves the rapidly growing wood pellet market, which is projected to reach USD 26.72 billion by 2033, directly driving demand for manufacturing equipment.

Market Overview and Growth Drivers

Wood Pellet Machine Market Context

The wood pellet machine manufacturing industry operates as a critical enabler of the global wood pellet market:

- Downstream Market Size: Wood pellet market valued at USD 13.99-18.09 billion in 2024

- Projected Growth: Wood pellet market expected to reach USD 26.72-32.88 billion by 2033

- Equipment Demand Driver: 6.9-15% CAGR in pellet production drives machinery replacement and expansion needs

Key Market Drivers for Equipment Manufacturing

- Production Capacity Expansion: Existing pellet producers expanding operations to meet growing demand

- New Market Entry: Companies entering pellet production driven by renewable energy opportunities

- Technology Upgrades: Replacement of aging equipment with higher-efficiency systems

- Geographic Expansion: Pellet production moving closer to consumption markets

- Regulatory Compliance: Equipment upgrades to meet environmental and safety standards

Equipment Market Size and Projections

Current Market Dynamics:

- Equipment Market Size: Estimated at USD 800 million – 1.2 billion globally in 2024

- Growth Rate: Projected 8-12% CAGR through 2033

- Technology Segments: Small-scale (1-10 TPH), medium-scale (10-30 TPH), and industrial-scale (30+ TPH)

📈 Market Growth Projection (2024-2033)

CAGR: 9-11% | Base Case Scenario Growth

Competitive Landscape and Market Share Analysis

📊 Global Market Share by Manufacturer (2024)

Market concentration shows moderate fragmentation with top 4 players holding ~31.5%

Tier 1 Global Leaders

CPM (California Pellet Mill Company) (United States)

- Market Share: Estimated 8%-12% of global market

- Market Position: Premium industrial pellet mill manufacturer

- Technology Focus: High-capacity ring die pellet mills and conditioning systems

- Industry Specialization: Animal feed, biomass, and industrial applications

- Geographic Strength: Strong presence in North America and international markets

- Competitive Advantages: Advanced conditioning technology, robust equipment design

Andritz Group (Austria)

- Market Share: Approximately 6%-10% of wood pellet machine market

- Business Model: Complete biomass processing solutions provider

- Technology Leadership: Advanced automation and control systems

- Project Scale: Large-scale industrial installations and turnkey projects

- Global Presence: International engineering and service network

- Competitive Advantages: Process optimization expertise, integrated solutions

Bühler Group (Switzerland)

- Market Share: Estimated 5%-8% of global market

- Technology Focus: Precision pelletizing and feed processing equipment

- Market Position: Premium equipment for high-quality pellet production

- Innovation Leadership: Advanced die technology and process control

- Service Network: Global service and support infrastructure

- Competitive Advantages: Swiss engineering quality, process consistency

RICHI Machinery (China)

- Market Share: 5%-9% of global wood pellet machine market

- Established: 1995, with over 25 years of manufacturing experience

- Global Reach: Operations in 93+ countries and regions

- Product Portfolio: Complete pelletizing solutions from feed preparation to finished product

- Technological Strength: 3%+ annual R&D investment, CAD/Solidworks design systems

- Manufacturing Capacity: Multiple production facilities with turnkey project capabilities

- Competitive Advantages: Cost-effective solutions, comprehensive service network, customizable systems

Tier 2 Regional Leaders

Bliss Industries (United States)

- Market Position: Diversified pellet equipment manufacturer

- Product Portfolio: Wood pellet machines, animal feed equipment

- Market Focus: North American market with international expansion

- Competitive Advantage: Multi-industry experience and expertise

Amandus Kahl (Germany)

- Market Position: Premium pelletizing technology provider

- Specialization: High-quality pellet mills and processing equipment

- Market Focus: European market with global presence

- Competitive Advantage: German engineering excellence

Market Concentration and Competitive Dynamics

Market Structure Analysis:

- Top 5 Manufacturers: Approximately 40-50% combined market share

- Top 10 Manufacturers: Estimated 65-75% combined market share

- Market Fragmentation: Significant number of regional and specialized manufacturers

- Competitive Intensity: Intense competition on price, technology, and service

Regional Manufacturing Hubs:

- China: Cost-competitive manufacturing base, led by RICHI Machinery

- Europe: Premium technology and engineering excellence (Germany, Austria, Switzerland)

- North America: Advanced technology and established market presence

- Emerging Markets: Growing local manufacturing capabilities

Technology Segmentation and Product Analysis

🔧 Market Segmentation by Capacity

Small-Scale (1-10 TPH)

Medium-Scale (10-30 TPH)

Industrial-Scale (30+ TPH)

By Capacity and Scale

Small-Scale Equipment (1-10 TPH)

- Market Share: 35-40% of unit sales

- Target Customers: Small producers, rural operations, startup companies

- Price Range: USD 50,000 – 300,000 per production line

- Key Players: RICHI Machinery, regional manufacturers

Medium-Scale Equipment (10-30 TPH)

- Market Share: 40-45% of unit sales

- Target Customers: Medium-sized producers, commercial operations

- Price Range: USD 300,000 – 1.5 million per production line

- Key Players: CPM, RICHI Machinery, Bühler Group

Industrial-Scale Equipment (30+ TPH)

- Market Share: 20-25% of unit sales, 50%+ of revenue

- Target Customers: Large-scale producers, industrial facilities

- Price Range: USD 1.5 million – 10+ million per production line

- Key Players: Andritz Group, CPM, Bühler Group

By Technology Type

Ring Die Pellet Mills

- Market Dominance: 85-90% of professional applications

- Technology Leaders: CPM, RICHI Machinery, Bühler Group

- Advantages: High capacity, consistent quality, durability

- Applications: Commercial and industrial pellet production

Flat Die Pellet Mills

- Market Share: 10-15% of professional applications

- Applications: Small-scale operations, specialty products

- Advantages: Lower cost, easier maintenance

- Limitations: Lower capacity, less consistent quality

⚙️ Technology Type Distribution

Complete Production Lines

- Market Growth: Fastest-growing segment

- Key Providers: RICHI Machinery, Andritz Group

- Components: Raw material handling, conditioning, pelletizing, cooling, packaging

- Value Proposition: Turnkey solutions, process optimization

Regional Market Analysis

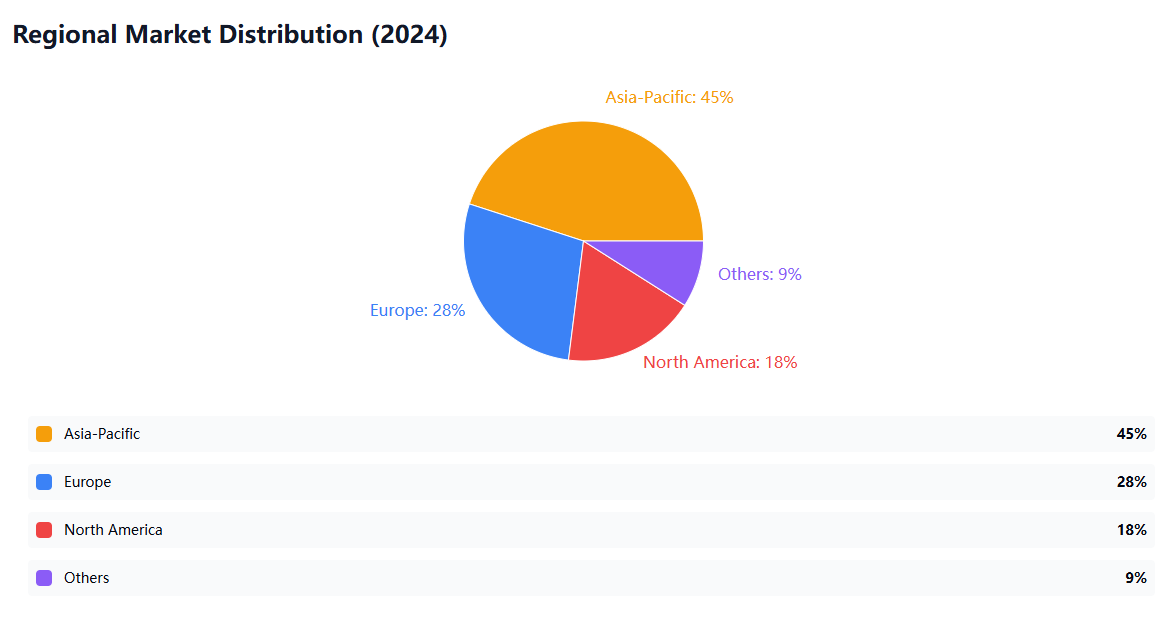

🌍 Regional Market Distribution (2024)

Asia-Pacific: Manufacturing Hub and Growing Demand

Market Characteristics:

- Manufacturing Center: China dominates global production capacity

- Leading Players: RICHI Machinery, multiple regional manufacturers

- Cost Advantage: Competitive manufacturing costs driving global exports

- Growing Demand: Expanding domestic pellet production capacity

China Market Dynamics:

- Domestic Demand: Rapidly growing pellet production for export and domestic use

- Manufacturing Expertise: Advanced pelletizing technology and production capabilities

- Export Strength: Major supplier to global markets

- Policy Support: Government incentives for renewable energy equipment

Europe: Premium Technology and Mature Markets

Market Position:

- Technology Leadership: Advanced pelletizing technology and automation

- Key Players: Andritz Group (Austria), Bühler Group (Switzerland), Amandus Kahl (Germany)

- Market Maturity: Established pellet production infrastructure driving replacement demand

- Regulatory Environment: Stringent environmental standards driving technology advancement

Market Trends:

- Efficiency Focus: Emphasis on energy-efficient and environmentally friendly equipment

- Automation Integration: Advanced control systems and Industry 4.0 integration

- Service Excellence: Comprehensive service and support networks

North America: Established Market with Innovation Focus

Market Characteristics:

- Mature Market: Well-established pellet production industry

- Technology Leaders: CPM, Bliss Industries

- Innovation Focus: Advanced conditioning and pelletizing technology

- Service Infrastructure: Comprehensive service and support networks

Growth Drivers:

- Capacity Expansion: Existing producers expanding operations

- Technology Upgrades: Replacement of aging equipment

- Export Demand: Production for European and Asian markets

Market Challenges and Opportunities

Industry Challenges

Competitive Pressure:

- Price Competition: Intense pricing pressure, particularly from Chinese manufacturers

- Technology Standardization: Risk of commoditization in standard equipment segments

- Service Requirements: Increasing demand for comprehensive service and support

Supply Chain Constraints:

- Raw Material Costs: Steel and component price volatility

- Component Availability: Supply chain disruptions affecting delivery times

- Skilled Labor: Shortage of experienced technicians for installation and service

Regulatory Compliance:

- Safety Standards: Increasing safety and environmental regulations

- Quality Requirements: Higher standards for equipment quality and performance

- Certification Costs: Increasing costs for international certifications

Growth Opportunities

Technology Innovation:

- Automation Integration: Advanced control systems and remote monitoring

- Energy Efficiency: Equipment designs reducing energy consumption

- Quality Improvement: Technology enhancing pellet quality and consistency

Market Expansion:

- Emerging Markets: Growing demand in developing countries

- New Applications: Equipment for alternative biomass materials

- Service Growth: Expanding aftermarket service and support opportunities

Vertical Integration:

- Complete Solutions: Turnkey project capabilities

- Digital Services: Remote monitoring and predictive maintenance

- Financing Solutions: Equipment financing and leasing programs

Investment Analysis and Strategic Recommendations

High-Growth Market Segments

Complete Production Line Solutions:

- Market Growth: Fastest-growing segment with highest margins

- Customer Preference: Increasing demand for turnkey solutions

- Competitive Advantage: Differentiation from component-only suppliers

- Investment Priority: R&D in system integration and process optimization

Medium-Scale Equipment (10-30 TPH):

- Volume Growth: Largest market segment by units and revenue

- Customer Base: Expanding middle-market pellet producers

- Technology Focus: Balance of capacity, efficiency, and cost-effectiveness

- Market Opportunity: Underserved segment in many regions

Automation and Digitalization:

- Technology Trend: Industry 4.0 integration and smart manufacturing

- Value Proposition: Reduced labor costs, improved consistency

- Market Differentiation: Advanced technology providing competitive advantage

- Investment Focus: Control systems, remote monitoring, predictive maintenance

Strategic Recommendations by Market Position

For Market Leaders (RICHI, CPM, Andritz):

- Technology Leadership: Continued R&D investment in advanced pelletizing technology

- Geographic Expansion: Strengthen presence in emerging markets

- Service Excellence: Expand service network and digital service capabilities

- Complete Solutions: Develop turnkey project capabilities

For Regional Players:

- Niche Specialization: Focus on specific applications or market segments

- Service Differentiation: Superior customer service and technical support

- Technology Partnerships: Collaborate with technology leaders

- Market Penetration: Strengthen position in home markets

For New Entrants:

- Technology Focus: Invest in advanced, differentiated technology

- Market Niche: Target underserved applications or geographic markets

- Partnership Strategy: Collaborate with established players

- Service Model: Develop comprehensive service capabilities

Future Market Outlook (2025-2033)

🔮 Market Scenarios & Key Statistics

Growth Scenario Analysis

Growth Projections

Conservative Scenario (7-9% CAGR):

- Equipment Market: Reach USD 1.8-2.2 billion by 2033

- Technology Evolution: Incremental improvements in efficiency and automation

- Market Dynamics: Steady growth driven by pellet market expansion

Base Case Scenario (9-11% CAGR):

- Equipment Market: Achieve USD 2.5-3.0 billion by 2033

- Technology Advancement: Significant automation and digitalization adoption

- Market Expansion: Growth in emerging markets and new applications

Optimistic Scenario (12-15% CAGR):

- Equipment Market: Exceed USD 3.5 billion by 2033

- Market Transformation: Rapid adoption of advanced technology

- Geographic Expansion: Significant growth in developing markets

Technology Trends and Innovation

Automation and Digitalization:

- Smart Manufacturing: Industry 4.0 integration and IoT connectivity

- Predictive Maintenance: AI-driven maintenance optimization

- Remote Monitoring: Real-time performance monitoring and optimization

- Process Control: Advanced control systems for consistent quality

Sustainability Focus:

- Energy Efficiency: Equipment designs minimizing energy consumption

- Environmental Compliance: Technology meeting stringent environmental standards

- Circular Economy: Equipment supporting waste-to-energy applications

- Renewable Integration: Systems optimized for renewable energy inputs

Market Evolution:

- Consolidation Trends: Industry consolidation creating larger players

- Service Integration: Equipment manufacturers expanding service capabilities

- Technology Convergence: Integration with other renewable energy technologies

- Global Standardization: Harmonization of international standards

Success Factors for 2025-2033

Technology Excellence:

- Innovation Leadership: Continuous R&D investment and technology advancement

- Quality Consistency: Reliable, durable equipment meeting customer expectations

- Process Optimization: Complete solutions optimizing entire production process

Market Positioning:

- Customer Relationships: Strong relationships with key pellet producers

- Geographic Presence: Global manufacturing and service capabilities

- Brand Recognition: Strong brand reputation in target markets

Operational Excellence:

- Manufacturing Efficiency: Competitive production costs and quality

- Service Network: Comprehensive service and support infrastructure

- Supply Chain Management: Reliable component sourcing and delivery

Conclusion

The global wood pellet machine manufacturing industry presents compelling growth opportunities driven by the expanding wood pellet market and increasing demand for renewable energy solutions. The industry is characterized by strong growth prospects, technological innovation, and increasing market consolidation.

Market leaders like RICHI Machinery, with its 5-9% market share, CPM, Andritz Group, and Bühler Group are well-positioned to capitalize on industry growth through technology leadership, geographic expansion, and service excellence. The competitive landscape offers opportunities for both established players and new entrants with differentiated technology and market positioning.

Success in this market requires strategic focus on technology innovation, customer relationships, and operational excellence. Companies that can deliver complete solutions, advanced technology, and superior service are positioned to capture disproportionate value creation in this growing global market.

The industry’s evolution toward greater automation, sustainability focus, and market consolidation creates both opportunities and challenges. Strategic investments in R&D, manufacturing capabilities, and service infrastructure will determine competitive positioning in the expanding wood pellet machine manufacturing market.

This report focuses specifically on wood pellet machine manufacturing equipment and is based on analysis of industry sources and market research as of September 2025. Market projections are subject to change based on economic conditions, regulatory developments, and competitive dynamics.